Biomass

Ygnis presents its new biomass boiler for industrial facilities

The new Varfire boiler from Ygnis has been created for the production of domestic hot water and heating, through the use of solid fuels such as pellets, crushed almond shells, pomace, olive pits and optionally chips. Thanks to the design of this boiler and its oversized surface, it is possible to obtain combustion efficiency of 87% with very low polluting emissions.

This new biomass boiler works up to 3 bars of pressure and is available in 12 models with powers between 100 and 1,600 kW. One of the great advantages of this boiler is that up to 500 kW it can be manufactured modularly, which allows its installation in difficult-to-access locations. In addition, Varfire complies with the EN 303/5 standard regarding solid fuel boilers. Likewise, it has a safety system against flame flashback through fuel injection with a double auger, its flooding valve and the safety probe in the double auger.

Another of the great advantages of Varfire is the design of its home and the large volume of water with which it works, which allows its operation without the need to install an additional buffer tank, this being only necessary in underfloor heating installations. In addition, the boiler has a manual ignition with the possibility of becoming semi-automatic through a switch located on the electrical panel.

Furthermore, Varfire is a boiler of great versatility thanks to the different possibilities of adapting the burner to the boiler; front, rear, right or left side, and also thanks to its design, since its large doors greatly facilitate the necessary inspection, cleaning and maintenance operations.

For all these characteristics, the new Ygnis biomass boiler is specially designed for industrial installations, guaranteeing great performance with semi-automatic operation.

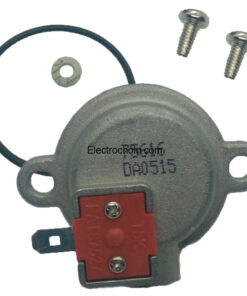

Junkers WR WRD Heater Pilot Solenoid Valve 87085012490

Junkers WR WRD Heater Pilot Solenoid Valve 87085012490